How Tanzania can combat aflatoxins

What you need to know:

- The findings of the trial, presented at a meeting in Dar es Salaam recently, come at a time when Tanzania is reported to be losing over $264 million due to aflatoxin poisoning, according to a 2016 report by the Nelson Mandela African Institution of Science and Technology.

A two-year field trial conducted in several sites across Tanzania found that a bio-control technique, known as AflasafeTZ could reduce contamination of food crops with the poisonous fungus (aflatoxins) by over 85 per cent.

The findings of the trial, presented at a meeting in Dar es Salaam recently, come at a time when Tanzania is reported to be losing over $264 million due to aflatoxin poisoning, according to a 2016 report by the Nelson Mandela African Institution of Science and Technology.

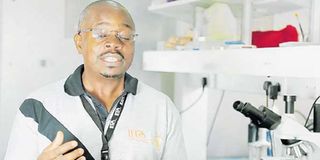

To delve into the hows and whys of the new findings, The Citizen’s Health Reporter Syriacus Buguzi interviewed Dr George Mahuku, a plant pathologist at International Institute of Tropical Agriculture (IITA), who is leading the research in Tanzania. Read on

Question: How serious is aflatoxin contamination in Tanzania?

Answer: Aflatoxin contamination is a big problem in Tanzania. Surveys conducted in 2012, which covered the entire country showed that more than 90 per cent of samples collected had detectable aflatoxin levels and 31 per cent had aflatoxin levels above the maximum allowable level for maize destined for human consumption (10 microgram/kg) and some samples had levels as high as 163 microgramg/kg).

Similar trends were also observed for groundnuts with more than 80 per cent testing positive for aflatoxins and 20 per cent of the samples had aflatoxin levels above maximum tolerable levels of 10 microgram/kg. The first reported case of acute aflatoxin poisoning occurred in 2016 when 65 cases were reported from two districts (Chemba and Kondoa) and 19 people lost their lives. In addition, aflatoxins have been linked with child stunting.

What’s this Aflasafe technology and how is it going to tackle this problem?

This is a biocontrol product which has been developed using fungi of the same family as those that produce aflatoxins. The fungi do not produce the poison, and as they multiply, they are able to outcompete the Aspergillus flavus.

This helps keep food crops safe. This technology is tailored for Tanzania using fungi exclusively from the country. That’s why it is known as Aflasafe TZ. It’s an all-natural product that is made up of fungus known as Aspergillus flavus that can never produce poison.

How will the farmers apply this?

The spores of atoxigenic strains (non-poison) are coated on roasted and sterile sorghum grains and are broadcast into a field two to three weeks before flowering of maize or 35–40 days after planting groundnuts (peanuts). The strains grow and multiply on sorghum after application and this initiates displacement of aflatoxin-producers in the field.

When applied by farmers at the right time, these products consistently reduce aflatoxin contamination by over 80 per cent and its effect carries into storage.

What is the significance of this outcome to Research and Development in tackling societal challenges?

This technology is farmer and environment friendly: very simple, easy to use, and an all-natural green solution. It has a huge potential for people in Africa, especially smallholder farmers.

Through improved health and protection from aflatoxins, as well as access to lucrative external markets, the farmers can earn more and improve their livelihood.

A study showed that for Tanzania, about 3,334 HCC cases per year are attributed to aflatoxin. These translate into 96,604 Disability Adjusted Life Years (DALYs) lost, which is equivalent to a median value of $25.2 million.

How is this problem of aflatoxicosis being tackled elsewhere and what are the gaps that our countries must fill?

In developed countries, aflatoxins are managed through strict regulation. This is because almost all people buy food from the supermarkets or regulated markets. Stringent regulations are imposed on suppliers who have to certify that the products entering the markets are within acceptable levels of contamination.

However, in Africa, regulations are largely ineffective as more than 70 per cent of the population living in rural areas eat what they produce.

This technology is, therefore, designed to cater for the aforementioned group. By minimizing contamination at farm level, this technology will contribute to solving one of the major health problems faced in Africa, while increasing access to (opening up) lucrative markets in the west, especially the EU.

This will have a significant impact on livelihoods of small holder farmers in Africa.

Why was it necessary to carry out this field trial?

Field trials are necessary to verify in a real-world context outside the lab and controlled conditions that the product is effective in reducing aflatoxin contamination in many geographical areas across Tanzania. This one, too was necessary to verify how the technology works in the real world. However, in addition, and through the efficacy trials, we created awareness of aflatoxins among farmers and trained then on how to correctly use Aflasafe to prevent aflatoxin contamination.

Tell us how you worked out the field trials and how you collaborated with the government on this.

In partnership with the ministry of Agriculture in Tanzania (a long-term partner), field trials to test the efficacy of AflasafeTZ were conducted in four regions and 11 districts in the 2016 and 2017 growing season. Fields (approximately 0.5 ha) in the target districts were selected by extension offices.

For selected farmers, meetings were conducted before the experiments were conducted, to give farmers information on the scope of the experiment, the objectives and goals and seek their concern.

All farm activities were according to farmers practice, except for the application of the product. For each field that was treated, there was a corresponding control (not treated) field that was 25-50 metres away from the treated field.

This was done to minimize microclimatic variations and to enable comparison of results.

AflsafeTZ was applied to selected fields between January and March 2016 and 2017, depending on when the farmers planted and these were harvested between April and July for each year.

Aflatoxin analysis was conducted immediately after harvest.